GVB Inspections

GVB Inspections prides itself of services of Quality, Inspection and Test delivered throughout South Africa by a specialized team.

Our field of specialization is, but not limited to, the oil and gas industries, mining, chemical and general industry, Farming and Wine Industry.

GVB Inspections employs a core team of inspectors and administration personnel and has access to contract personnel certified as: SAQCC – CP Competent Person for in-service Pressurized Vessels, Boilers and Pressurized Systems.

In-service Inspection Service

Government Approved Inspections

Conformance to assessments of SANS 347

Know The Duties of Manufactures

Ensuring requirements is subjected to SANS 347

Check The Duties of Importers & Suppliers

Liability of manufacturer in terms of regulations

Duties of Users

Regulations under section 44 of the Act

Ensure Correct Pressure Equipment Marking

Required nameplate information for vessels

Schedule Inspection Today

About GVB Inspections (Pty) LTD

GVB Inspections (Pty) Ltd is an in-service inspection company for pressurized equipment whose inspectors have collectively 55 years inspection experience. GVB Inspections also has access to a consultant who singularly has 43 years inspection experience. Our field of specialization is, but not limited to, the oil and gas industries, mining, chemical and general industry, Farming and Wine Industry.

GVB Inspections prides itself of services of Quality, Inspection and Test delivered throughout South Africa by a specialized team. It is our policy to render services of a high standard to our clients thereby combining maximum efficiency of operation with customer satisfaction.

This is achieved through maintenance of a well-documented Quality Management System which is SANAS(ISO/IEC) 17020:2012 compliant. Health and Safety is held in high regard and forms one of the corner stones of our documented Quality Management System.

Our People

GVB Inspections employs a core team of inspectors and administration personnel and has access to contract personnel certified as: SAQCC – CP Competent Person for in-service Pressurized Vessels, Boilers and Pressurized Systems.

Collective Experience

Inspection Experience

General Pressure Equipment Regulations

General Requirements in Accordance With

Department of Labour Occupational Health and Safety Act, 1993

General Requirements

(1) Any person who manufactures, imports, sells, offers or supplies any pressure equipment described in these Regulations for use in the Republic shall ensure that such equipment complies with these Regulations.

(2) Any person who erects or installs any pressure equipment for use in the Republic shall ensure, as far as is reasonably practicable, that it is erected or installed in a safe manner and without risk to health and safety when properly used.

(3) All pressure equipment for use in the Republic shall be categorized and submitted to the applicable conformance assessments of SANS 347 in addition to the requirements of the relevant health and safety standard incorporated into these Regulations under section 44 of the Act.

Duties of manufacturers

(1) The manufacturer shall have an obligation to ensure that all equipment designed and manufactured for use in the Republic shall be conformity assessed and subjected to the requirements set out in SANS 347.

(2) Subject to the requirements set out in the relevant health and safety standard incorporated into these Regulations under section 44 of the Act, the manufacturer shall ensure that the pressure equipment as manufactured, modified, inspected, tested or repaired is safe and without risks to health when properly used.

(3) Subject to the requirements of this regulation a manufacturer shall issue a certificate of manufacture for all pressure equipment supplied, with a verification signature by an approved inspection authority when so required.

(4) Subject to the requirements of this regulation a manufacturer shall comply with any other duty assigned to the manufacturer in these Regulations.

(5) A manufacturer who determines that pressure equipment in use has a latent defect shall advise the chief inspector in writing forthwith thereof and of measures being taken to correct the defect

Duties of importers and suppliers

(1) Importers and suppliers shall ensure that pressure equipment sold complies with the requirements of these Regulations.

(2) The importer shall assume the liability of the manufacturer in terms of these Regulations.

(3) Any pressure equipment that requires a permit to be issued by an organisation approved by the chief inspector shall ensure that such approval is obtained by the importer or manufacturer before the pressure equipment is placed in the market: Provided that such equipment shall comply with the relevant health and safety standard incorporated into these Regulations under section 44 of the Act.

Duties of Users

(1) The user shall ensure that the pressure equipment is operated and maintained within its design and operating parameters.

(2) The user shall, subject to the relevant health and safety standard incorporated into these Regulations under section 44 of the Act –

(a) provide the manufacturer, repairer or modifier with comprehensive information of the operating or intended operating conditions of the pressure equipment, including the characteristics of the fluid and operating parameters of other connected pressure equipment, where reasonably practicable;

(b) ensure pressure equipment has a certificate, issued by the manufacturer, including a

verification signature by an approved inspection authority when required, which certifies that the pressure equipment has been designed and manufactured in accordance with

the relevant health and safety standard incorporated into these Regulations under section 44 of the Act;

(c) ensure pressure equipment has a certificate issued by the repairer or modifier, including

a verification signature by an approved inspection authority when required, which certifies

that the pressure equipment has been modified or repaired in accordance with the relevant health and safety standard incorporated into these Regulations under section 44 of the Act;

(d) ensure that pressure equipment has a certificate issued by an approved inspection authority before commissioning, where applicable; and

(e) ensure that a gas system has a valid certificate issued by an authorised person.

Pressure equipment marking

Every manufacturer of pressure equipment shall cause the pressure equipment to be marked in accordance with the relevant health and safety standard incorporated into these Regulations under section 44 of the Act.

Every manufacturer shall cause a data plate to be permanently fixed in a conspicuous place to any steam generator or pressure vessel with the following minimum particulars:

-

Name of manufacturer;

-

Country of origin;

-

Year of manufacture;

-

Manufacturer’s serial number;

-

Reference number, date and edition of the health and safety standard;

-

Design pressure in units of Pascal;

-

Design temperature for both minimum and maximum in degrees Celsius;

-

Capacity in cubic metres;

-

Unique mark of an approved inspection authority as applicable; and

-

The hazard category in accordance with the requirements of SANS 347.

In the case of composite pressure equipment the following information shall be included in addition to that referred to in sub regulation (2):

-

The resin system of the corrosion barrier/lining;

-

The resin system of the structural wall; and

-

The name and specific gravity of the medium for which the vessel was designed.

No person may remove a marking or data plate referred to in this regulation or wilfully damage or alter the particulars marked thereon, except as provided in this regulation.

A user shall ensure that any modification that changes the original design conditions is identified by affixing an additional data plate.

A user shall ensure that a data plate is affixed to any steam generator or pressure vessel that has been re-certified: Provided that where the manufacturer is unknown, the user responsible for the re-certification shall be deemed to be the manufacturer.

Certificates and Accreditations

General Enquiries

CP-Pressure Vessels

Contact Person: George Van Biljon

Email Address: info@gvbinspections.co.za

Cell: 082 851 2752

Admin and Office Personnel:

For any inquiries or complaints please contact:

Joleatha or Tamlyn

Tel: 022 487 1441

Email: info@gvbinspections.co.za

Call For Inspection:

(022) 487 1441

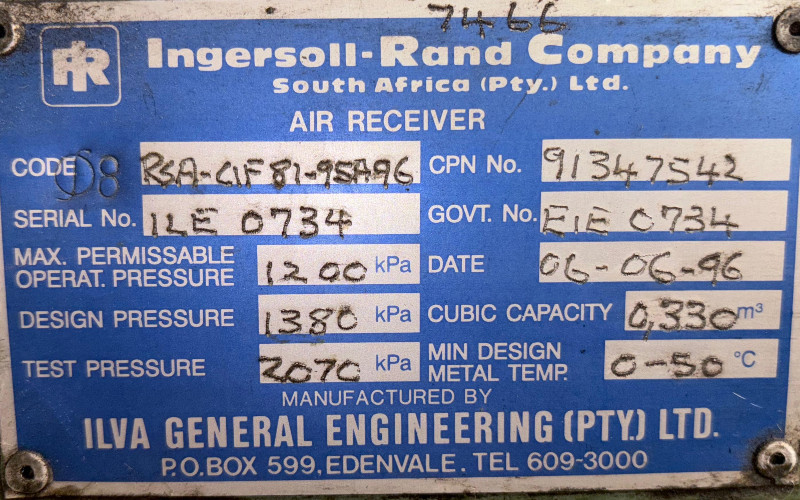

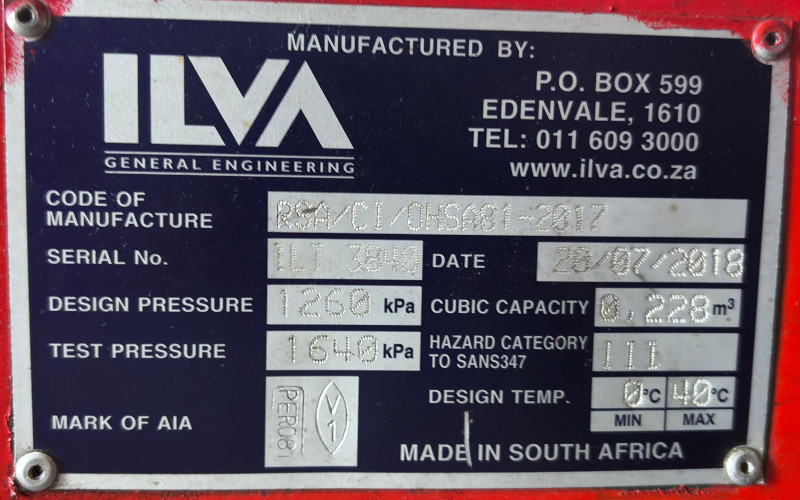

Vessel Nameplate Information

Minimum required Nameplate information for vessels designed in the PRE-VUP, VUP and PER

Pre-Vup (Prior to 23/10/1992)

– Year Manufactured

– Serial Number

– Design Pressure

Vup (23/10/1992-30/09/2009)

– Manufacturers Name

– Country of Origin

– Design code

– Year manufactured

– Serial Number

– Design Pressure

– MPOP

– Operating temperature

– Capacity

– AIA Stamp

PER (01/10/2009-Present)

– Manufacturers Name

– Country of Origin

– Design Code

– Year manufactured

– Serial number

– Design Pressure

– Max Design Temperature

– Min design temperature

– Capacity

– AIA Stamp

– SANS haz cat